React. Accelerate.

REACC Engineering Ltd is an Engineering and Design Consultancy specialising in equipment for use in challenging offshore and subsea environments.

React loads. Accelerate towards the engineered solution.

About Us

REACC Engineering Ltd is a UK-based business providing specialist engineering services to Energy, Renewables and Defence industries.

Founded in January 2025, we provide on-demand expert engineering to help businesses turn innovative ideas into reality.

Our mission is to be a trusted engineering partner that businesses can rely on to deliver high-quality, value-adding engineering design every time.

Our attention to detail and rigour sets us apart. We listen intently to your requirements and aspirations, then combine them with our deep knowledge of industry standards, regulations and sound engineering practice to ensure your equipment is truly fit for purpose.

Services

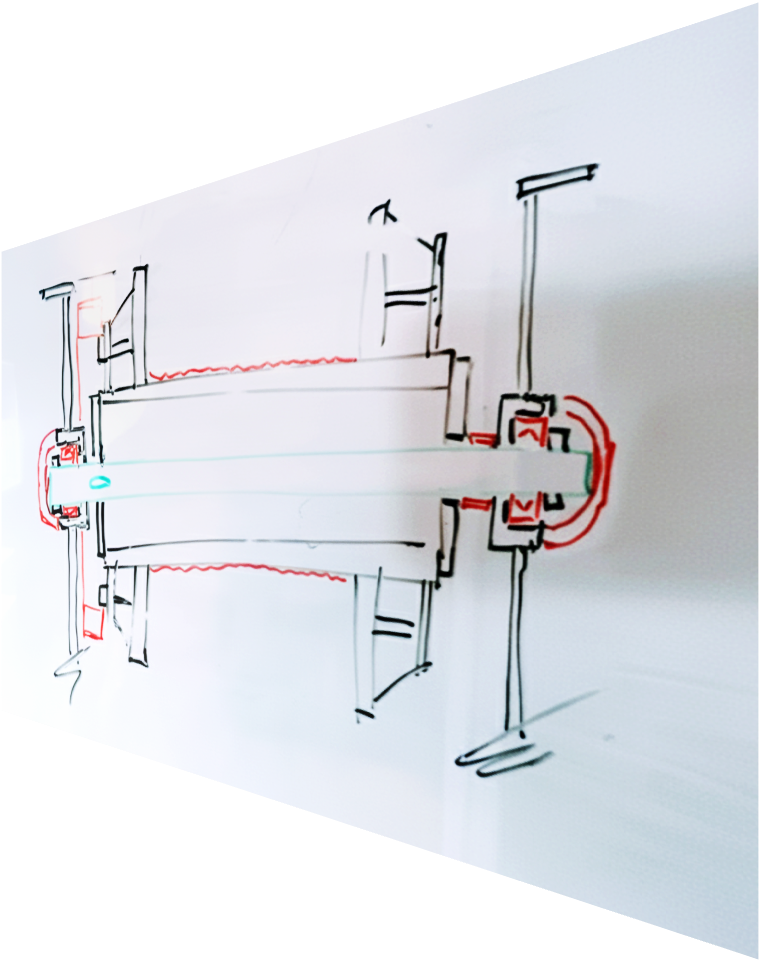

Conceptual Design

From a whiteboard sketch to a well-developed FEED study, REACC can assist you and your system design requirements.

REACC quickly asks the pertinent questions and thoroughly defines the must-have and the nice-to-have criteria for your product or system.

Identifying the parameters and knowing the applicable rules are key to getting to the end solution faster.

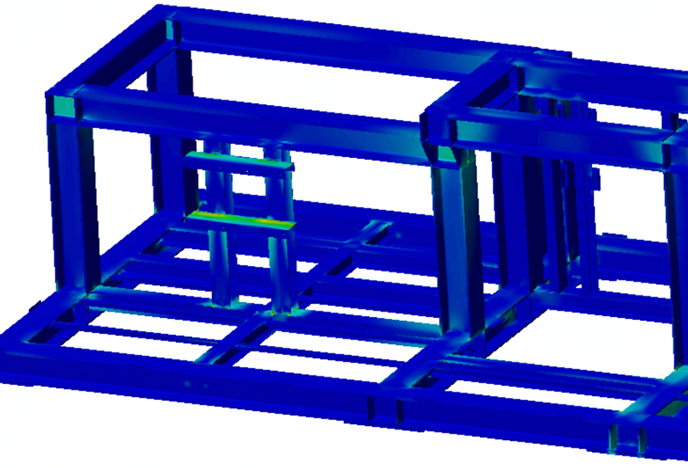

Detailed Design

Many can create attractive CAD models, but turning them into something manufacturable is another matter. Design for Manufacture (DFM) is a core strength of REACC Engineering, and producing expertly crafted drawings is key to successful builds.

We work closely with fabricators and machine shops, aligning designs with their capabilities and constraints to minimise cost and avoid unnecessary complexity.

Selecting the right manufacturing techniques is critical to efficient assembly and long-term reliability. From grade 10.9 M24 bolts to 5 mm rivets, we’ve been there.

All drawings are produced to BS 8888 and we can tailor our drawings and documents to suit your document control requirements.

Product Development

We specialise in taking ideas from concept to reality. Whether you have a one-off build or an early-stage prototype, we help transform it into a product that can be manufactured reliably and at the right scale.

From initial design and prototyping through to production planning and full lifecycle management, we provide a clear roadmap to bring your vision to market.

Our approach ensures that every stage from idea generation and development to testing, refinement and production is handled with care, efficiency and technical expertise.

Engineering Calculations and Analysis

A core competency of REACC is mechanical calculations and understanding of engineering first principals. Our calculations are not only to tick a box, they demonstrate our understanding of the requirements and always reference a source - no more guessing where factors and values come from.

We validate by calculation using our carefully selected tools:

Hand Calculations using Mathcad Prime

Beam Element Frame Analysis using Autodesk Inventor for rapid optimisation

Finite Element Analysis using Autodesk Inventor Nastran. We utilise ANSYS if the simulation warrants it.

Through-Life Support

Our experience supporting operations and service teams with equipment in the field or installed gives REACC Engineering advantage over many design consultants. When Murphy’s Law kicks in, we can support solve the problem.

Problem solving and Root Case Analysis

Upgrades to existing systems

Refurbishment work planning and execution

Risk assessment

Expertise

Lifting Appliances and Handling Systems

Possessing over a decade of experience delivering high-quality designs for offshore launch and recovery, pipe lay and cable lay equipment with design appraisals by Lloyds Register, DNV and ABS.

We have designed safe and effective launch recovery systems for diving bells, hyperbaric rescue chambers, manned submersibles, workover system baskets and ROVs.

Expertise in systems classed to:

DNV-ST-0378 - Offshore and platform lifting appliances (formerly DNV 2.22)

Lloyds Register: Lifting Appliances in a Marine Environment

ABS Certification of Lifting Appliances

Various other IACS member rules for certification and classification

Diving Systems

Saturation diving is highly-regulated and must remain when the weather turns.

Deploying humans, at pressure, safely to depths of 300msw requires an attention to detail and great rigour to ensure diver’s lives are adequately protected.

In accordance with IMCA D 014 International Code of Practice for Offshore Diving, international and project-specific standards, we have have the experience of delivering designs that provides the functionality and the appropriate level of safeguarding to enable divers to carry out their work as safely as possible.

Our experience includes:

Diving bell external and internal layouts

Hyperbaric evacuation systems

Handling equipment

Diving support equipment

Underwater Vehicles

Proven track record of delivering elements of new-build and through-life upgrades of manned submersibles and evaluation of submarine interfaces:

NATO’s Submarine rescue System (NSRS) - “Nemo” and associated rescue and intervention equipment

Indian Navy’s twin submarine rescue systems based in Mumbai and Visakhapatnam

Australian Navy’s “LR5” and handling system

Unmanned exploration submersibles

Various Navy Submarines

Work-class ROVs

Containerised and Modular Systems

With a knack for laying out complex systems for build, operation and maintenance, REACC are well placed to package equipment into optimally-sized modules for single builds or higher volume production.

We have the experience of deploying DNV 2.7-3 Portable Offshore Units to 1500m water depth and ISO 20’ and ISO 40’ containers custom-built to house generator powertrains, hydraulic power units, control cabins and many more applications.

Meet the Team